Home / ST200 sand blasting machine for dental implants surface texturing

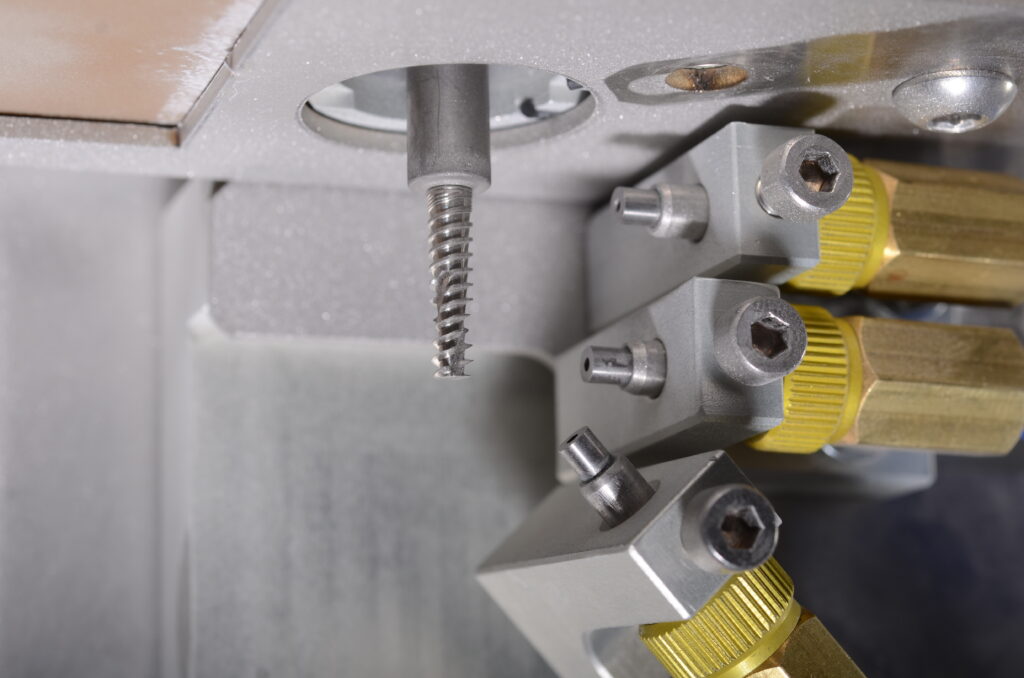

The ST200 system is an innovative solution for medical screws and dental implants texturing using abrasive media blasting.

The machine’s operation is fully automated and programmable, using a friendly and easy-to-use touch screen interface. With an intense and precise blasting, the machine gives excellent results, with minimal blasting material usage.

The machine’s operation is very quiet and has an advanced air filtration system, which guarantees very clean and quiet operation. This makes the machine suitable, not only for industrial spaces, but for office spaces as well.

Air supply: dry air 5-7 bar.

Air Consumption: Approx. 0.3 m3/min

Power: 380VAC 3 x 16A

Dimantions (W x H x D): Approx 1290 x 2426 x 908 mm

Weight: 650 kg

Capacity up to 250 implants per hour

Accurate blasting using 1-1.5 blasting nozzles.

Economic use of blasting media

Un limited blasting programs

Programing flexibility using "G code״

Small foot print

Built in dust collecting system with filters auto clean

Can be used for aluminum oxide, Titanium oxide and Calcium phosphate.

Easy and low cost maintenance

Media recycling and autofill options

The AF108 is equipped with a 45-liter internal media tank that automatically replenishes the ST200 blasting tanks when they are depleted. Used blasting media is automatically transferred from the ST200 to the AF108 for recycling. The AF108 is electrically connected and controlled by the ST200.

To schedule a meeting, leave us a message

© All Rights Reserved to Rotenberg – integrated systems